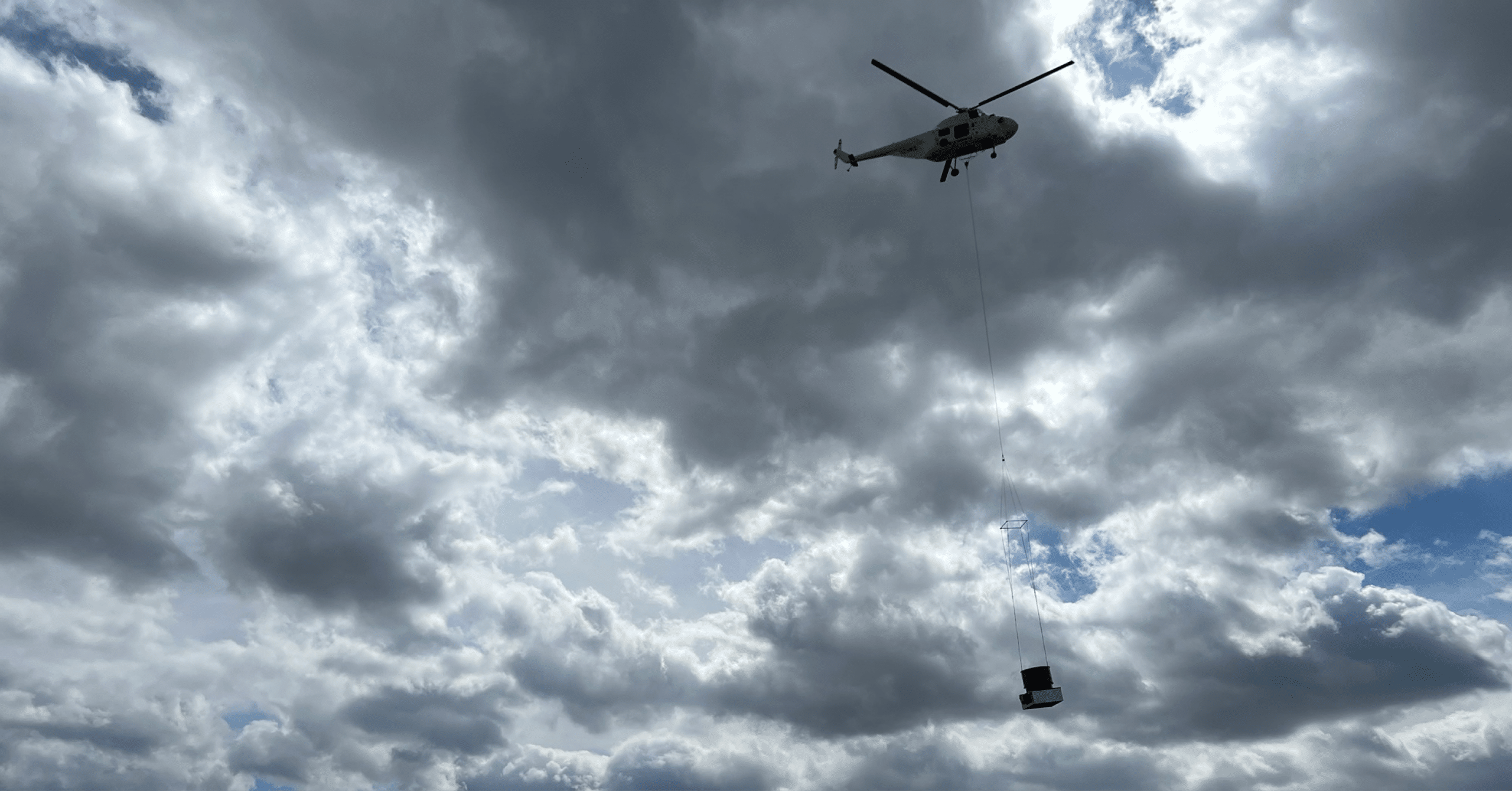

Our team, led by our mechanical contractor, The Comfort Group, executed a sight rarely seen in the Upper Cumberland – 29 exhaust fans being lifted by helicopter to the roof of the Portobello America manufacturing plant. This process allowed our team to get all 29 fans set within a day, whereas if we had utilized a crane to lift them individually the work would’ve taken over a week!

The heli-lift was chosen due to the site proximity to the Upper Cumberland Regional Airport and the ability to save over 4,000 man-hours. This strategy required extensive coordination between The Comfort Group, the pilot and the TWF team.

The procedure for a heli-lift is fairly labor intensive as far as the prep work goes. Over 60 hours were utilized to clear the site and remove any debris that could be blown about by the air from the rotors of the helicopter. We also had to have the trash dumpsters and porta-potties moved so that they would not blow over, and our team of workers had to prep the roof curbs, gasketing, and pre-rigged the units on the ground.

The lift itself took 3 hours with 13 men. There were 9 men on the roof – 4 to set the units, 4 more to screw them down and a signal man. Additionally, there were 3 men on the ground hooking the units up to the helicopter and a signal man.