February 18, 2026

Provided by Matt Jacobson, T.W. Frierson Construction Technology Leader

Construction is a people-first industry. Long before software, sensors, or models existed, skilled professionals were planning, coordinating, and building complex projects with ingenuity and grit. That reality matters, because any conversation about construction technology that forgets the intelligence, adaptability, and professionalism of the field is destined to miss the point.

Technology does not succeed in construction because the field needs to be “fixed.” It succeeds when it respects how work actually gets done and quietly helps great teams perform at an even higher level.

I believe construction technology has reached an inflection point. Not because we have more tools than ever, but because we finally have the opportunity to use them with intention. When technology is aligned with field realities, it does not disrupt craftsmanship it amplifies it.

The Gap Between Technology and Jobsite

Our industry is surrounded by innovation. New platforms promise efficiency, automation, and clarity. Many of them look impressive in demos, and some truly are powerful. Yet adoption often struggles, and it’s tempting to frame that as resistance from the field. Field teams are not resistant to technology. They are resistant to anything that introduces uncertainty, risk, or additional burden without a clear payoff. That is not reluctance; it is professional judgment.

I have seen systems deployed with the best intentions with tools that promised to eliminate rework or centralize information into a single source of truth. Technically, they worked. Practically, they often lived outside the rhythm of the jobsite. They added steps without removing others. Crews were asked to do more documentation, more data entry, more context switching all while still being responsible for the same outcomes.

When adoption slowed, it was easy to conclude that the technology itself had failed. More often, what failed was the alignment around it. Existing workflows remained intact, incentives stayed the same, and the additional effort required to make the tool successful was felt most acutely in the field.

The takeaway is not that technology is inherently flawed. It is that technology must earn its place on the jobsite. When it meaningfully reduces friction, removes uncertainty, and supports how work actually gets done, it stops feeling like an obligation and becomes something the field relies on, an Asset.

Why Field Skepticism Is Actually a Strength

One of the most misunderstood dynamics in construction is field skepticism toward new tools. From the outside, it can look like resistance to change. From the inside, it is usually risk management.

Superintendents, foremen, and craft professionals are accountable for real outcomes like schedule, safety, and quality. They have learned, through experience, that unproven systems can create delays they will be asked to explain later. Their caution is not fear-based, it is responsibility based.

The encouraging reality is when technology genuinely solves a problem, the field adoption happens quickly. No mandate required. When a tool removes rework, eliminates waiting, clarifies sequencing, or reduces exposure to hazards, the field does not need to be convinced. They recognize value immediately.

That insight shapes how I approach construction technology.

A Field-First Philosophy

When someone brings me a new tool or platform, the first question I ask is not about cost or features. I ask about impact on our current process state. Does this integrate naturally, or does it introduce disruption? In some cases, disruption can be healthy. It can force us to think differently and improve how we work. But disruption without a clear outcome is simply friction.

Before I support the use of any technology on a T.W. Frierson project, several criteria must be met.

- The technology must be proven to be an asset in terms of human interaction to outcome. Tools do not create value on their own, people using it do. I need to understand the why and the how behind the technology, not just what it does. I also need confidence that there is a strong product support organization behind it. Field personnel do not have the bandwidth to troubleshoot systems that fail under pressure.

- The technology must respect the flow of field work. If it causes too much disruption to how people already operate, it will not be used. No amount of mandate changes that reality.

- We intentionally curate interest and build a core group of power users. These individuals help load-balance implementation, generate excitement, and provide practical feedback. Bringing together people from different groups with different backgrounds allows us to evaluate technology through multiple lenses and identify where it can truly benefit the business.

Jobsite critical issues always come first. Technology that directly supports safety, constructability, coordination, and schedule reliability is prioritized. “Nice to have” innovation follows a longer vetting process. Integration, workflow impact, personnel capacity, and long-term return on investment all matter. The goal is not to chase novelty, but to expand our capabilities responsibly while supporting our teams and delivering exceptional outcomes for our clients.

Where Time Is Really Lost and How We Can Win It Back

Productivity discussions in construction often focus on execution. In my experience, time is more often lost due to lack of clarity, not lack of effort. Building Information Modeling is a powerful example. Many organizations still underutilize BIM’s full potential. When projects are truly built virtually, when conflicts are resolved digitally and the model becomes the backbone for downstream workflows, field execution becomes calmer, more predictable, and more efficient.

Prefabrication builds on that foundation. With strong modeling, prefabrication improves quality, sequencing, and safety. Work moves from congested, elevated, weather-exposed environments into controlled shop settings. Cleanup decreases. Scrap decreases. Exposure decreases. These benefits compound across the project lifecycle.

Even with highly skilled teams, waiting remains one of the biggest hidden drains on time. Technology alone cannot eliminate those delays, but well-designed systems can dramatically reduce them by improving information flow, visualization, and shared understanding.

Technology as Confidence, Not Control

I think the most productive way to frame construction technology is as a tool for reducing uncertainty.

Virtual Design and Construction elevates the quality of conversations before work begins. Today’s models allow teams to see not just what is being built, but how it will be built. When field teams are involved early, their insight improves sequencing, constructability, and quality. A shared model creates shared intent.

Robotic Total Stations carry that clarity into execution. Coordinated models become precise field layout, reducing interpretation, accelerating installation, and eliminating rework. The value is certainty. Crews can trust that what they are building matches what was planned.

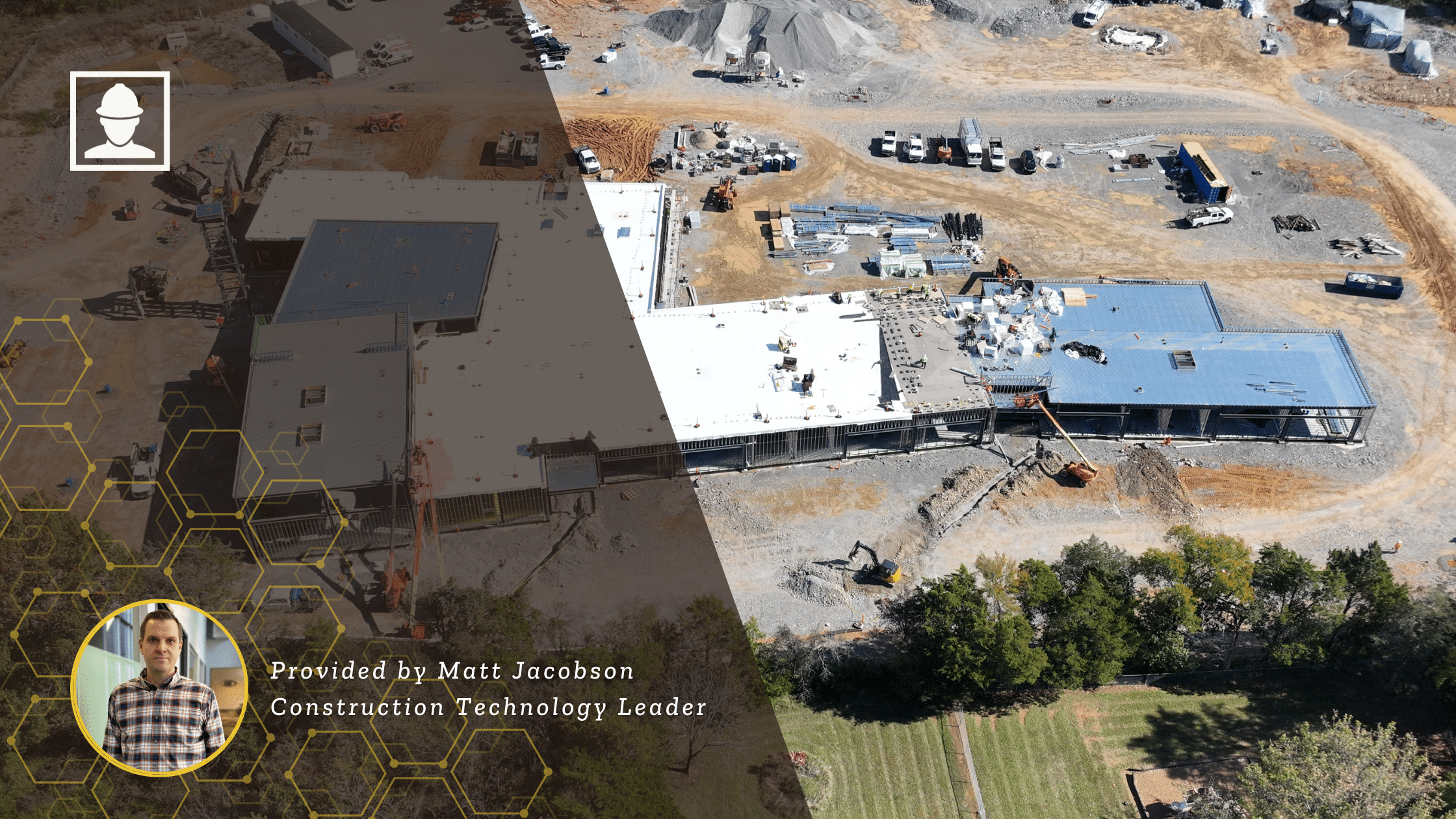

Drones extend that clarity into the physical world. They allow teams to see conditions that were once guessed at (i.e. unsafe areas, inaccessible façades, evolving site conditions). High-resolution imagery and photogrammetry provide reliable data for progress tracking, QA/QC, and dispute resolution. They enhance awareness without increasing exposure.

Artificial intelligence is often misunderstood. The reality today is far less dramatic and far more practical. AI is being used to analyze images, surface trends, and assist with pattern recognition. It is powerful, but not magical. Its effectiveness depends on data quality, integration, and thoughtful implementation.

When implemented deliberately, these technologies do not control the field, they support it by removing guesswork and enabling better outcomes.

A Moment That Changed the Conversation

On a recent project, a large visitor center was envisioned as a signature space, featuring semi-exposed ceilings that highlighted the structural steel, with complex and highly visible MEPF systems weaving through the room. The design intent was compelling, but it had been developed without BIM.

Once the trade partners modeled their scopes and the models were federated, the reality of the space came into focus. The 3D environment quickly revealed where architectural intent conflicted with constructability. System visibility, routing, beam penetrations, lighting layout, and fire protection head placement simply did not align spatially. These were not issues that would have surfaced during traditional plan reviews. Historically, they would have been discovered in the field and late in the schedule.

Instead, the team gathered around the model for an all-day coordination session. Designers and trade contractors worked together in a shared digital environment, exploring options, resolving constraints, and making decisions in real time. The conversation shifted from defending drawings to solving real problems. The model became a common language, allowing design intent, means, and methods to be evaluated simultaneously.

What stood out afterward was not just that the conflicts were resolved, it was how the process changed the team. The design team saw firsthand that BIM and coordination are not simply about clash detection. They are about creating a shared vision, resolving constructability concerns early as a team, and reducing downstream risk. The construction team avoided rework that would have been solvable in the field, but only through unnecessary schedule pressure, added cost, and increased risk.

I witnessed firsthand how the process built trust. Designers and builders were no longer reacting to problems downstream, they were collaborating upstream. BIM did not replace expertise, it aligned it.

Safety Is the Ultimate Measure

Schedule pressure is inevitable. How we respond to it matters. When uncertainty creeps in, coordination can break down. Planned sequences collapse. Prefabrication strategies are abandoned. People improvise. That is when risk increases.

Better upfront planning changes that trajectory. Virtual coordination removes conflicts before crews encounter them. 4D sequencing helps prevent trade stacking and supports safer work environments. Prefabrication moves high-risk activities into controlled settings, reducing exposure to falls, awkward lifting, and fatigue.

Beyond the physical benefits, there is a psychological one. When teams trust the plan, when information is reliable and sequencing makes sense, work becomes more methodical. Decisions are calmer. People are not rushing to solve problems that should have been resolved earlier. Every hour spent coordinating virtually is an investment in safer, more confident field execution.

A Better Mental Model for Construction Technology

The most damaging misconception about construction technology is that it is about tools and software. It is not. Construction technology is about improving decision quality. It is about reducing uncertainty so skilled professionals can do what they already do best, build.

When technology is treated as a support system for people, it becomes transformative. When we get it right, technology does not compete with construction expertise, it amplifies it.

If I had to reduce construction technology to one sentence, it would be this:

“Construction technology exists to give the right people the right information at the right time, so experience, not guesswork, drives decisions.”

That is a future worth building together.